Premise:

The customer is a pharmaceutical company delivering its products by air.

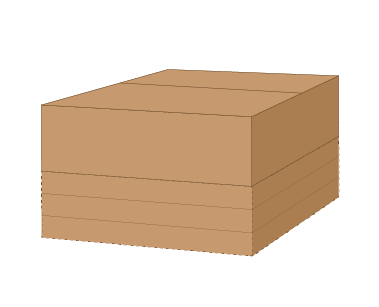

- Use a standard size Gaylord to protect the pallets

- The boxes are standard in dimension (customers need to cut them to adjust the height)

- Each adjustment takes time and yields an inconsistent result.

Customer expectations

- Improve the protection of the products

- Reduce the number of SKUS in inventory for each size of pallets

- Improve the ease of adjusting the height of the pallet shields

Challenges:

- The employees are cutting the corners of the shield and cut out the unnecessary sections: time consuming and high risk of injuries ( Using an exacto knife)

- The unnecessary sections were thrown out while they could have been used to protect the pallets.

Solution:

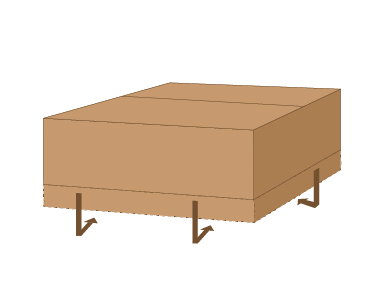

- We developed a shield built with the cardboard flutes running horizontally instead of the standard vertical flutes in order to ease the folding of the unnecessary panels .

- Adds protective thickness to the bottom of the pallets

- Eliminated the need to cut with pre scored folds. The result is square and professional.

Results:

- 1 SKU adjustable to each pallet heights

- Less cutting

- Better pallet protection

- Reduction of the packaging time